While having a movement is great, it really needs somewhere to live, so I started down the path of designing a home for my little brass machine.

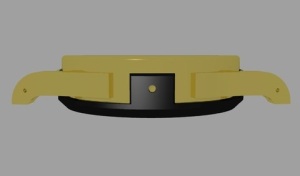

My main criteria for the case is that it adequately protects and allows good viewing of the movement, and wears comfortably.. ideally some water resistance would be nice. I have taken some cues from an industrial context, and made the case quite solid, especially on the case horns (where the band attaches) as this is quite often where cases are damaged and need re-finishing. I also have designed the case with rapid prototyping in mind, this way I can have the case made in a variety of materials, and even do combinations, for my renders I used a gold case with an ABS plastic case back, but silver or bronze is also quite a possibility.

Side note on Rapid Prototyping:

This process, also called “3D printing” is where a model is built layer by layer using a combination of a material and also a “filler” that is placed anywhere there would be a void. Once the model is finished, the filler material is quite often just blown away with compressed air, leaving the finished piece.

Over recent years, the materials able to be used in this process have become quite varied, from a brittle yet very detailed wax, which is able to be used for casting in precious metals, to a stainless steel based powder that can be sintered into a solid steel object, though the minimum thickness of the steel is about 1-2mm vs .1mm for the wax. A variety of plastics can also be “printed” including ABS plastics which are quite strong and durable.

To secure the case main and case back I plan on using 4 bolts or screws, inserted from the sides, top and bottom of the case.

The front crystal is going to plexiglass (plastic) to begin with, as this will show how many times I hit the case on the front, as plexi marks easily, yet doesn’t shatter, I will look into fitting a domed sapphire crystal when I find a supplier at a reasonable cost.

The rear crystal will be a mineral crystal to begin with to be replaced with sapphire at some point.

While getting quotes to have the case made in either wax or ABS plastic, I decided to mill a prototype of the front of the case, just to see if it looked at least partly ok, the only issue I still have is that the watch is fairly large.

The case measures 60mm long, and 44mm wide (definitely not a small watch by any means)

While getting quotes for the rapid prototyping I came across a company that could machine my case instead from solid metal, so I also obtained a quote for this service.

When the quotes came in, there was not a lot of difference in price between getting the case machined in steel, or made in a plastic or wax, plus the lead time required was not too long. The go-ahead was given and the process started.

Can you name your machining provider? The possibility of machined steel for not much more cost compared to 3D printing is very interesting!

Hi Hugo, the case machining was done through a local rapid prototyping company that has since been absorbed into a larger unit.. though there are a surprising amount of companies around that will do the same with a quick google and a bucketload of phone calls and emails.. I do need to warn you though, the closer to the final product, the more it costs, so if I had wanted it done to the level required to fit everything straight into would be many times the cost of a 3d print, just due to the time involved. 🙂

Tom