Due to popular demand, another blog post!!! (well ok, a couple of people asked me about this)

When I bought my milling machine, I was limited largely by the amount of money I had to spend, my understanding of what I wanted to do, and my limited (at the time) understanding of what different mills were capable of doing.

I will try and break this down in to a few basic criteria, though ideally a workshop would have multiple machines with each one appropriately tasked. The key to this is knowing what each machine is capable of, and what is needed for each operation required..

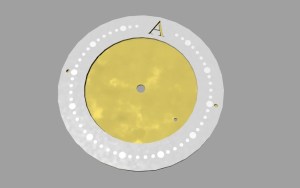

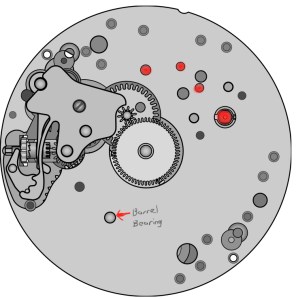

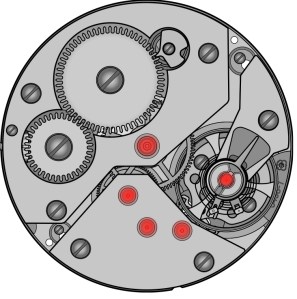

as an example, for making a mainplate, ideally you need something that is capable of accurately pointing/drilling the holes for all of the jewels, screws, pins etc, as well as a machine for milling all of the recesses for the wheels, levers etc.. for making wheels and pinions a rigid machine that has precise angles and indexing capability (the ability to rotate a precise angle to form the right number of teeth on each wheel and pinion) and also able to hold the correct cutters.

At the time I believed the Sherline could fill all these requirements and more!! I opted for a CNC version as I have a decent understanding of electronics, and liked the idea of programming it and letting it rip!! With around 7 years of tinkering with the mill I have a much greater understanding of what the machine is capable of, and while with a large amount of work it could perform all the duties I want of it, it would probably not be worth it in the long run.

Given an unlimited (or at least very large) amount of money, I would purchase 3 separate machines (and somewhere to put them all)

Machine No 1 – For precise placement of holes – A Hauser M1 jig borer, with the ability to co-ordinate drill holes to within 1/1000 of a mm, can’t get much better than this, though largely used as decorations in workshops…

http://www.lathes.co.uk/hauser/page4.html

Machine No 2 – For general milling operations – A Haas CNC Mini Milling station, fast milling speed, 10 tool changer… whats not to like.. apart from the price tag…

http://www.haascnc.com/mt_spec1.asp?id=SMINIMILL&webID=MINI_MILL_VMC

Machine No 3 – For wheel and pinion cutting – An Aciera F1, super precise, rigid as anything, made for doing this.. or a Dixi, unfortunately the dixi hasn’t been made for over a decade, and the Aciera is still quite expensive.. but they would round out any workshop superbly…

http://www.lathes.co.uk/aciera/

Of course the mill is only part of the equation, ideally a number of lathes would also be desired for the ideal workshop, notably a Schaublin 70.. using this for all turning operations, items can be transferred between this and at least the Aciera, as they share the same tooling..

The ideal milling machine is incredibly rigid, so that even at the extremes of its travels there is no flexing of the mill axes, which would create inaccuracies in the process.

The other main quality required for a good mill is accurate leadscrews, these are the parts of the mill that provide the movement of the axes, these need to be smooth running so that they don’t bind which would create jerky cuts.. and there also needs to be no slop or play in the threads, as this would change the repeatability.. you need to be able to move an axis forward and back, and have it return to the same place each time, this is what will add the most value (and cost) to a machine. most machines use a standard V cut thread to accomplish this, but on high end CNC machines this is replaced with a “ballscrew”

My sherline has issues in both of these departments, it is largely made of aluminium, which has (for something made of metal) a larger amount of flexibility than cast iron or steel, as well as this the way the spindle is mounted has its own issues as well… There are now ballscrew kits available for my mill, though the cost is fairly prohibitive given the initial cost of the mill..

At the end of all this, the milling machine I have is the best I could get for the money I have spent on it, and the things I have learnt while using it will stand me in good stead for when I am able to afford my ideal trio..