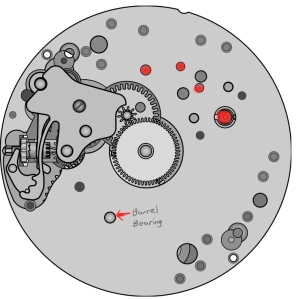

I started machining as soon as possible, a process of around 8 hours solid. only to find that I had gotten confused when translating my measurements to the computer, because of this the recess that holds the barrel was machined too deep, this has the effect of not leaving enough material for the centre wheel jewel to seat into, and also removing some material around the setting mechanism.. Not good!

Re-working the machining file and tooling up, I re-made the mainplate, This time the alignment between the front and back was off by about 0.5mm, as was the next one, so I finally figured out a method of lining the front and back of the plate up a bit more effectively. I had been relying on using locating holes in each plate lining up with matching holes in a perspex machining jig.

The new method involves moving a tapered point inside holes in the plate, adjusting slightly, moving to the next hole and so on, until the point is in the centre of all of the holes. Using this method I machined a set of both mainplate and bridges, all appearing to line up within about 1/10th of a mm.

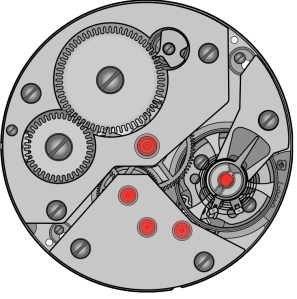

I enlarged all of the bridge hole to the proper sizes for all of the jewels, and fitted them all, then did the same for the train bridge. As I test fitted the train wheels it became apparent that something was not quite right, the 4th wheel with the extended pivot for the small seconds hand would no longer fit through the jewel. After a quick modification and removal of the long pivot, the wheel would fit. Success!! Steady pins were added to the train wheel bridge so that it would locate in the correct place every time, taking a cue from Peter Speake-Marin I made these pins tapered, so that as the bridge is lowered it fits neater than if they had been completely parallel.

Short lived success though.. after placing the rest of the wheels in to the plates the first 2 wheels in the train mesh a little tightly and the 3rd and 4th wheel do not touch at all! and to top everything off, I’ve run out of brass to mill plates out of and most people are closed over Christmas / New Year.. so at least this gives me some time to work on the dial and hands…